Mastering the Art of Fasteners: A Guide to Efficient and Secure Joining Solutions Mastering the Art of Fasteners: A Guide to Efficient and Secure Joi

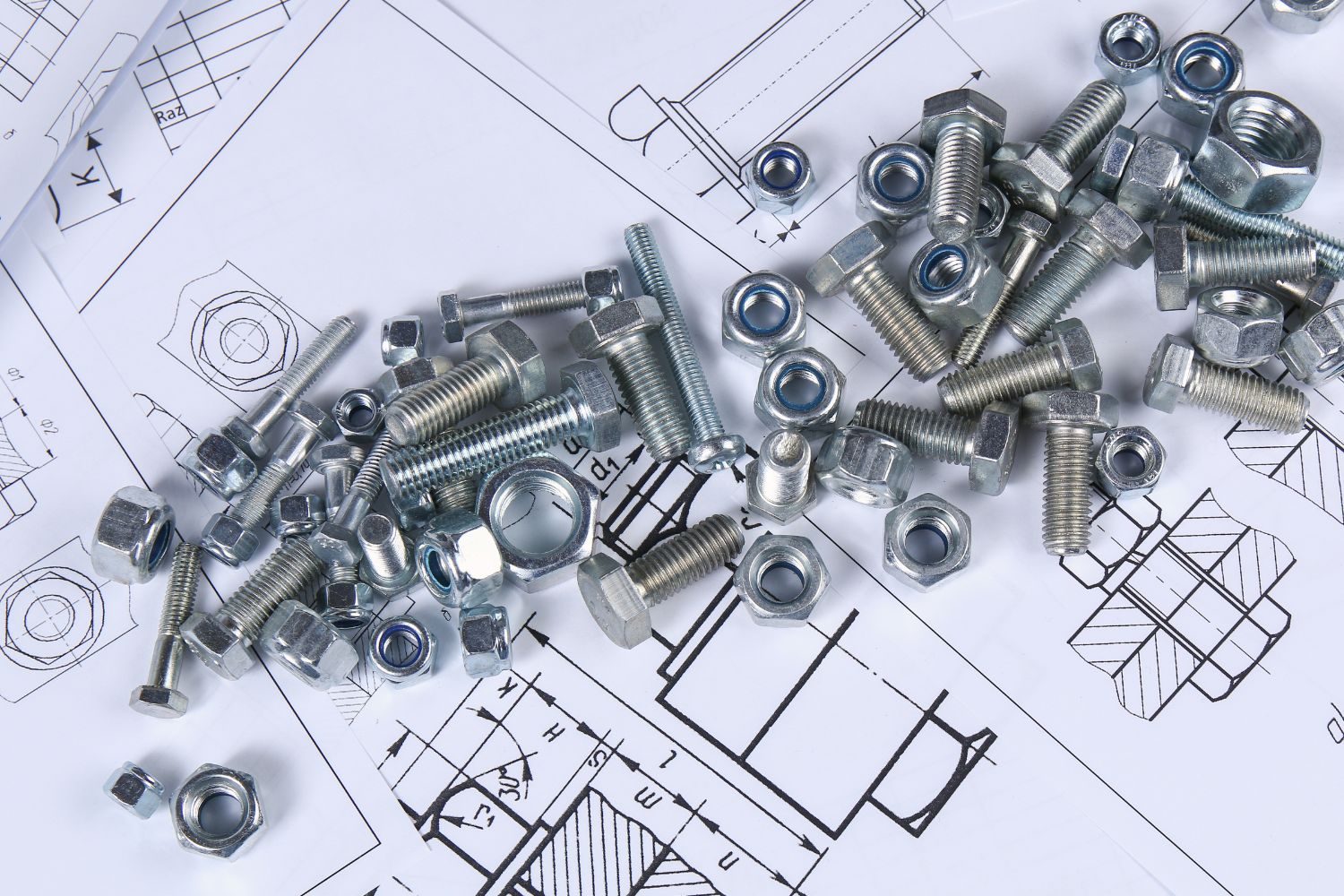

Mastering the Art of Fasteners: A Guide to Efficient and Secure Joining Solutions

Mastering the Art of Fasteners: A Guide to Efficient and Secure Joining Solutions: When it comes to construction, manufacturing, or even DIY projects, one often-overlooked but crucial aspect is the choice and application of fasteners. These seemingly small components play a significant role in ensuring the stability, reliability, and longevity of structures and products. In this comprehensive guide, we will delve into the world of fasteners, exploring their types, applications, and tips for selecting the right ones to achieve efficient and secure joining solutions.

Understanding the Basics

Fasteners are hardware devices used to mechanically join or secure two or more objects together. They come in a wide variety of shapes, sizes, materials, and designs, each tailored to specific purposes. The primary goal of fasteners is to create a secure and reliable connection between components, with factors such as load-bearing capacity, environmental conditions, and aesthetics in mind.

Types of Fasteners

- Nails and Screws: These are the most common types of fasteners, used for basic woodworking, construction, and DIY projects. Nails are typically driven into materials like wood, while screws require pre-drilled holes and offer a stronger grip due to their threading.

- Bolts and Nuts: Bolts are threaded fasteners that require a nut to secure two or more parts together. They are commonly used in machinery, automotive applications, and structural connections.

- Rivets: Rivets are permanent fasteners that are often used in metalwork and aerospace applications. They are inserted into pre-drilled holes and then deformed to create a strong, secure joint.

- Clips and Clamps: These fasteners are designed for easy installation and removal. Clips are used to hold objects together without the need for tools, while clamps provide temporary or adjustable fastening solutions.

Factors to Consider When Choosing Fasteners

- Material: The choice of material depends on factors like the environment (indoors vs. outdoors), corrosion resistance (stainless steel for rust-prone areas), and load-bearing requirements.

- Load-Bearing Capacity: Different fasteners have varying load-bearing capacities. It’s crucial to select fasteners that can handle the anticipated weight and forces.

- Connection Type: Consider whether the fastener will provide a permanent or removable connection, as well as the ease of disassembly if needed.

- Aesthetics: In some applications, the appearance of the fasteners matters. For instance, decorative screws might be used in furniture construction.

- Installation Method: Some fasteners require special tools or equipment for installation, so it’s important to factor in the availability of these tools.

Best Practices for Secure Fastening

- Proper Hole Preparation: Whether you’re using screws, bolts, or rivets, ensuring the holes are the right size and properly aligned is essential for achieving a secure connection.

- Torque Control: When using bolts and nuts, proper torque ensures that the fasteners are neither too loose nor too tight, maintaining structural integrity.

- Consider Shear and Tension: Depending on the forces the joint will experience, choose fasteners that can handle shear (sliding forces) and tension (pulling forces) appropriately.

- Maintenance and Inspection: Regularly inspect fasteners for signs of wear, corrosion, or loosening, and replace them as needed to prevent failures.

Conclusion

Mastering the art of fasteners is a skill that can greatly impact the quality and longevity of your projects. By understanding the types of fasteners, considering important factors during selection, and following best practices for installation, you can achieve efficient and secure joining solutions that stand the test of time. Whether you’re a professional in the field or a DIY enthusiast, taking the time to learn about fasteners is a step toward craftsmanship and reliability.

COMMENTS